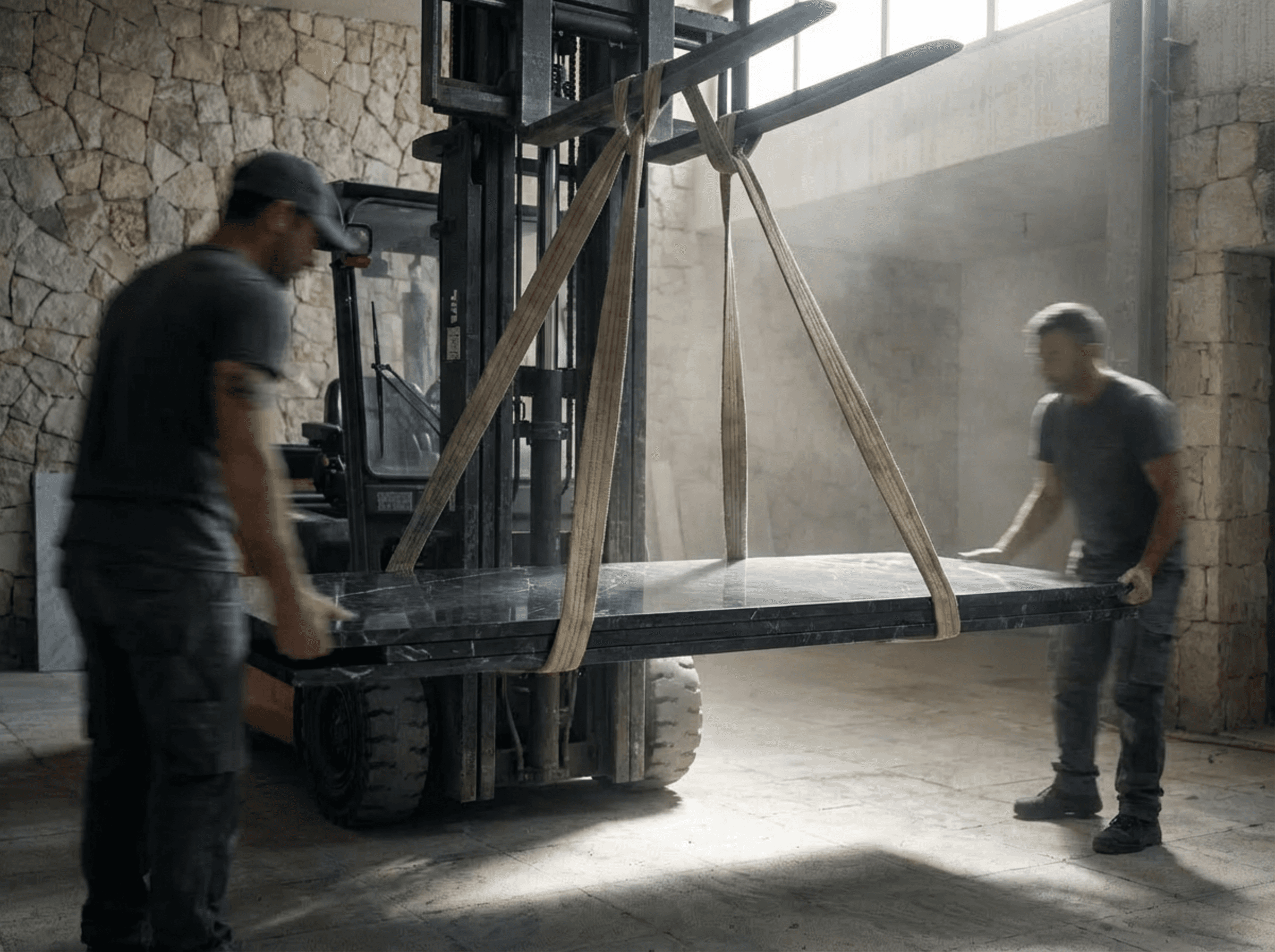

A space designed for weight and movement

Managing a warehouse for stone is a logistical discipline. Every block, slab and finished element carries significant weight, and the environment must be organised around safe, controlled movement. Storage systems are arranged according to thickness, material type and project timeline, allowing the team to access pieces without unnecessary handling. A well structured space reduces risk and keeps each surface in its best condition from arrival to installation.

Precision before fabrication

Before slabs enter fabrication, they undergo detailed inspection. Light, alignment and surface integrity are evaluated to understand how the material will behave once cut. The warehouse becomes an extension of the workshop, providing the controlled environment needed to detect inconsistencies early. This preparation ensures that each slab enters machining with clarity, reducing waste and supporting consistent results.

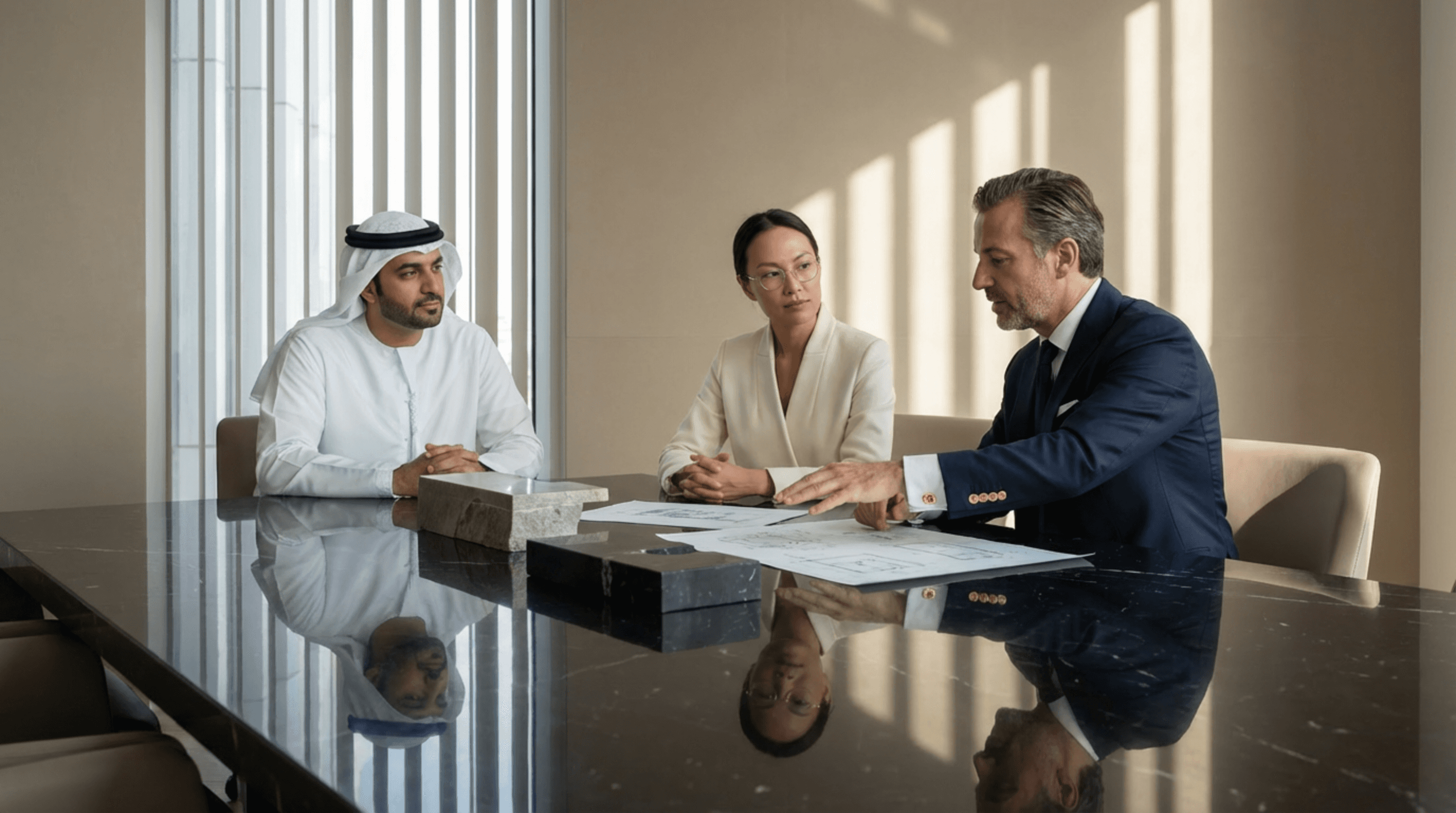

Coordination that supports the entire project

Heavy materials demand careful sequencing. Deliveries must align with site readiness, and every element must leave the warehouse in the correct order to avoid delays or rehandling. The team tracks each piece throughout its journey from quarry to project location, maintaining a calm, structured flow. Good warehouse management is not just logistics, it is a foundation for the precision that clients experience in the final installation.